The outboard engine is a crucial component of a boat’s power system, directly affecting its operational efficiency and safety. Among the various parts of the outboard engine, the water pump impeller is often overlooked but is an essential wear item. Today, we will delve into the role of the water pump impeller, common issues, and how to properly maintain it, helping you better understand this critical part.

Role of the Water Pump Impeller

The water pump impeller is one of the core components of the outboard engine’s cooling system. Its primary function is to pump water into the engine to ensure it maintains an appropriate temperature during operation. When the outboard engine operates at high speeds, it generates significant heat. If the cooling system fails, the engine could overheat, leading to severe damage or even a shutdown. Therefore, the condition of the water pump impeller directly impacts the performance and longevity of the outboard engine.

The impeller is typically made of rubber or composite materials, offering flexibility and wear resistance. Its design allows it to draw in water and pump it into the engine’s cooling passages at high speeds. However, due to its high-speed rotation and prolonged exposure to water flow, the water pump impeller is one of the most easily worn-out components in the outboard engine.

Common Issues and Causes

- Wear and Deformation

The water pump impeller operates at high speeds and is subject to friction, leading to wear. Additionally, the water may contain silt, debris, and other impurities, which accelerate wear. If the impeller becomes deformed or excessively worn, the water pump’s efficiency will decrease, and cooling performance will suffer. - Aging and Cracking

Over time, the materials of the impeller (especially rubber) will age and become brittle, potentially cracking. An aged impeller cannot effectively pump water, leading to engine overheating. - Debris Jamming

Debris such as water plants or plastic fragments may get caught in the impeller, affecting its normal operation. If not cleaned promptly, this could lead to impeller damage or water pump failure.

How to Maintain the Water Pump Impeller

- Regular Inspection

It is recommended to inspect the water pump impeller every 100 hours of operation or at least once a year. If any wear, deformation, or aging is detected, the impeller should be replaced immediately. - Clean the Water Pump System

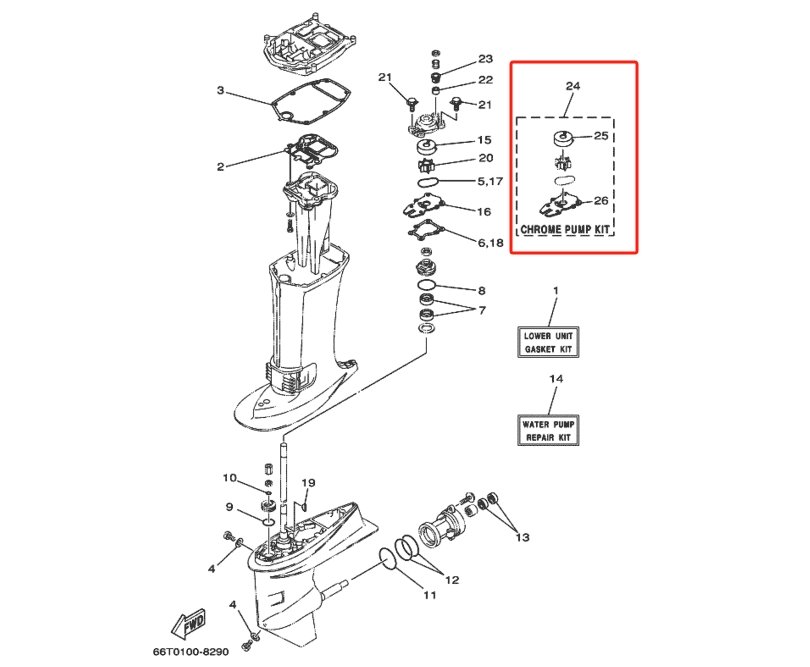

When replacing the impeller, it’s also a good idea to check other parts of the water pump system (such as the pump housing and seals) and clean any possible debris. - Use High-Quality Parts

Choose original or high-quality water pump impellers (such as those from YAMAHA, Mercury, etc.) to ensure durability and performance. Poor-quality impellers may wear out quickly or even damage the water pump system. - Be Mindful of Operating Conditions

Try to avoid operating the outboard engine in murky or debris-heavy waters to reduce impeller wear.

Recommended Products: High-Quality Water Pump Impellers

Impellers are made from high-quality materials, offering excellent wear resistance and durability, suitable for a variety of outboard engine models.

Conclusion

Although the water pump impeller is small, it plays an indispensable role in the outboard engine’s cooling system. Regular inspections, timely replacements, and selecting high-quality parts can significantly extend the life of the outboard engine and ensure safe voyages. If you have any questions regarding water pump impellers or other outboard engine parts, feel free to contact us anytime, and we will provide professional advice and services!